When a neighbor is in need, there’s no question that you do what you can.

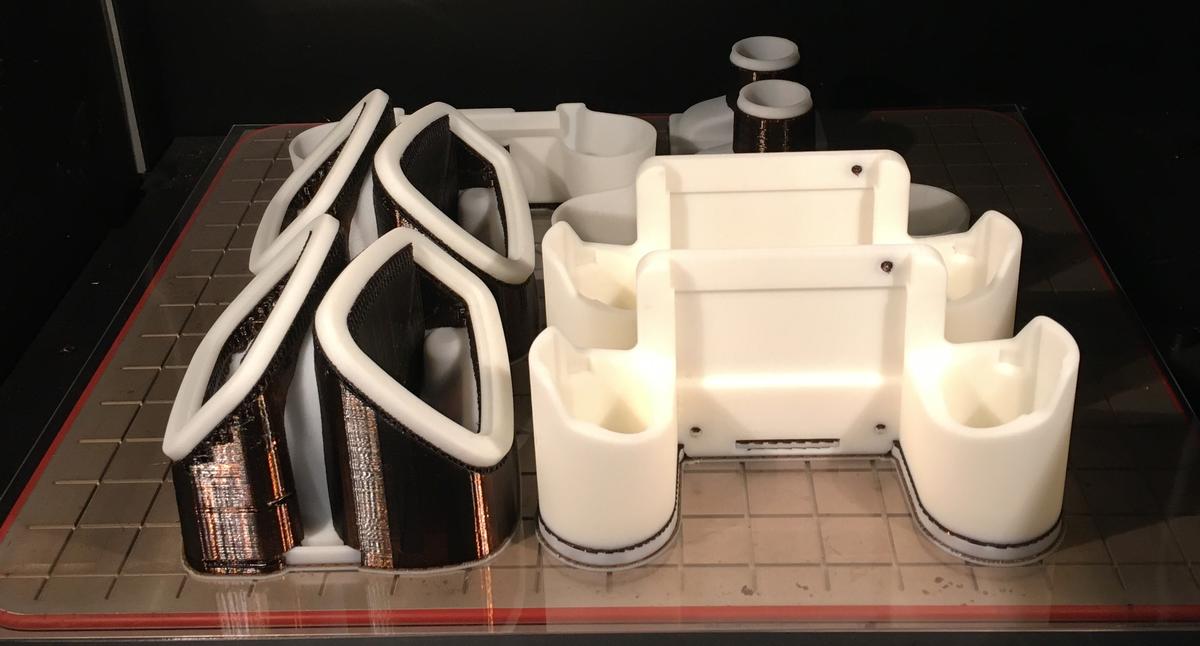

Cirrus Aircraft, the Natural Resources Research Institute's back door neighbor, wanted to help with the regional COVID-19 respirator need by designing, programming and building parts using their 3D printing capabilities. But the parts are complicated and time consuming to build, even with modern additive manufacturing machines.

The call went out across the state that any and all 3D printing capabilities be put to use to help build the parts. NRRI’s Additive Manufacturing Lab was pulled out of hibernation and Kory Jenkins – working safely in the lab – got busy.

Cirrus partnered with Duluth manufacturer Frost River to build Positive Air Pressure Respirators, known as PAPRs. They’re a step up from the N-95 face masks for front line workers. The two local businesses are working with Essentia Health and St. Luke’s Hospital to meet the needs of their staff.

Jenkins worked with Cirrus to troubleshoot some of the build process to move the project forward.

“Our fused deposition modeling equipment is 17 years old and a bit slow by today’s standards,” explained Jenkins, manager of NRRI’s lab. “But we’ll be able to contribute parts for four PAPRs and some spare parts. We’re happy to help meet this need.”

Cirrus and Frost River have set a goal to produce 200 PAPRs by May 1. They are working with health care professionals to evaluate their effectiveness.

Learn more about NRRI.